Tsarin embossing na PVC marmara zanen gado da alaka da farko dogara a kan extrusion fasahar, tabbatar da inganci da daidaito samar.(Hoto1) (Hoto2)

Na farko, tsarin extrusion yana samar da tushe na PVC. Bayan haka, ta hanyar tsarin lanƙwasa mai zafi (matsi mai zafi da laminating), takardun fina-finai masu launi daban-daban suna manne a saman takardar, suna ba da launi mai launi, wanda ya kafa harsashi don cimma nau'o'in abubuwan gani iri-iri kamar dutsen kwaikwayo ko maganin marmara.(Hoto3) (Hoto4)

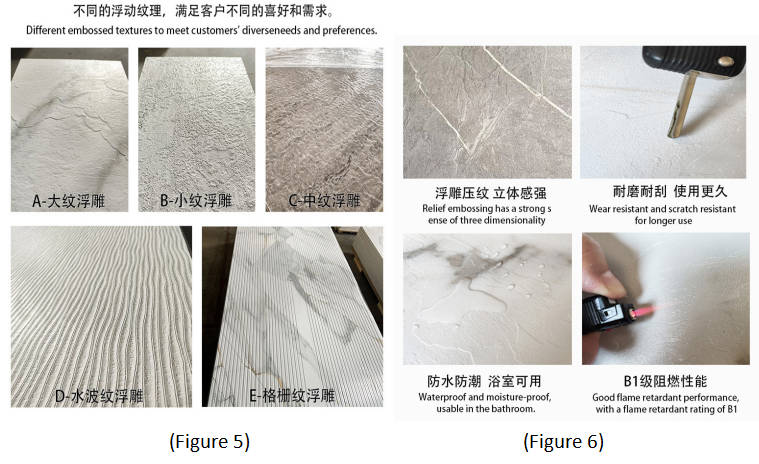

Makullin maɓalli don ƙirƙirar rubutun da aka ɗora shine latsawa tare da abin nadi. Wadannan rollers sun zo cikin nau'i-nau'i iri-iri, ciki har da manyan alamu, ƙananan alamu, ripples na ruwa, da kuma tsarin gasa. Lokacin da takardar PVC, bayan lamination, ta wuce ta cikin rollers embossing a ƙarƙashin yanayin da ake sarrafawa da matsa lamba, ƙayyadaddun nau'ikan nau'ikan nau'ikan na'urorin suna canjawa wuri daidai. Wannan tsari yana haifar da sakamako daban-daban na taimako, yana sa bangarorin suna da nau'i uku da ƙarewa.(Hoto5) (Hoto6)

Wannan hade da extrusion, zafi matsi lamination, da embossing nadi latsa damar samar da PVC bangarori da daban-daban launuka da embossed alamu, kamar gasa juna PVC jijiya jijiya bangarori. Ya dace daidai da abubuwan da aka zaɓa daban-daban da buƙatu masu amfani na abokan ciniki daban-daban a cikin kayan ado na ciki da sauran fannoni.

Lokacin aikawa: Yuli-31-2025